Spectroscope

Classification:

Product Introduction

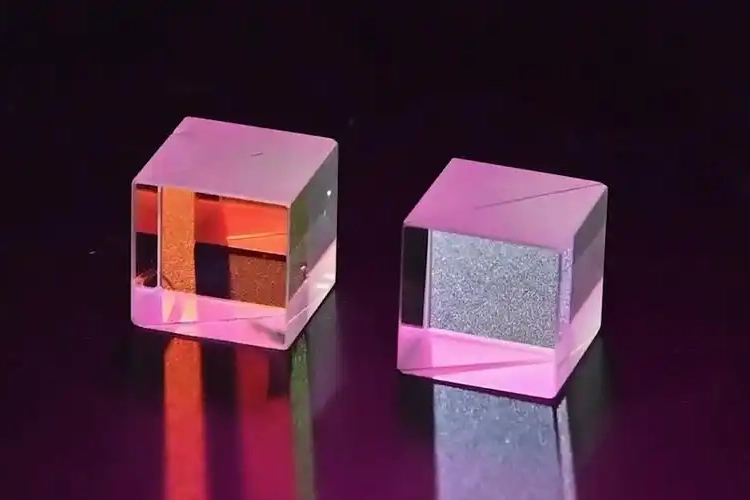

A beam splitter is an optical instrument that divides a beam of light into two beams. It is a crucial component in many interferometers. Beam splitter designs typically involve a glass cube formed by bonding two glass prisms along their diagonals, or a coating of aluminum on a glass plate, enabling a specific wavelength of light to be equally divided when incident at a 45-degree angle.

· Various beam splitter types, including: polarizing, non-polarizing, and laser line

· Custom solutions from prototype manufacturing to mass production

· Expert design and application specialists to handle complex coating and geometric requirements

Duchuang Optics is a leading manufacturer of cube and plate beam splitters (from UV to IR wavelengths). Our expert optical design and manufacturing engineers develop custom solutions for prototype manufacturing and mass production, supporting your entire product development process. World-class metrology ensures all beam splitters meet your application requirements. What can we do for you?

Our beam splitters are manufactured using various SCHOTT, Ohara, and CDGM materials. Whether you need a few beam splitters for prototyping, dozens for pre-production, or large quantities for mass production, we can tailor a solution to your application. Certain values may depend on the material and other required Specification.

Key words:

Prism and flat sheet

Previous Page

Next Page

Any more questions?

DuChuang photoelectric service for you!

Related Products

Laser splitting components include gratings, laser cube prisms, laser polarization cube prisms, and harmonic separators.

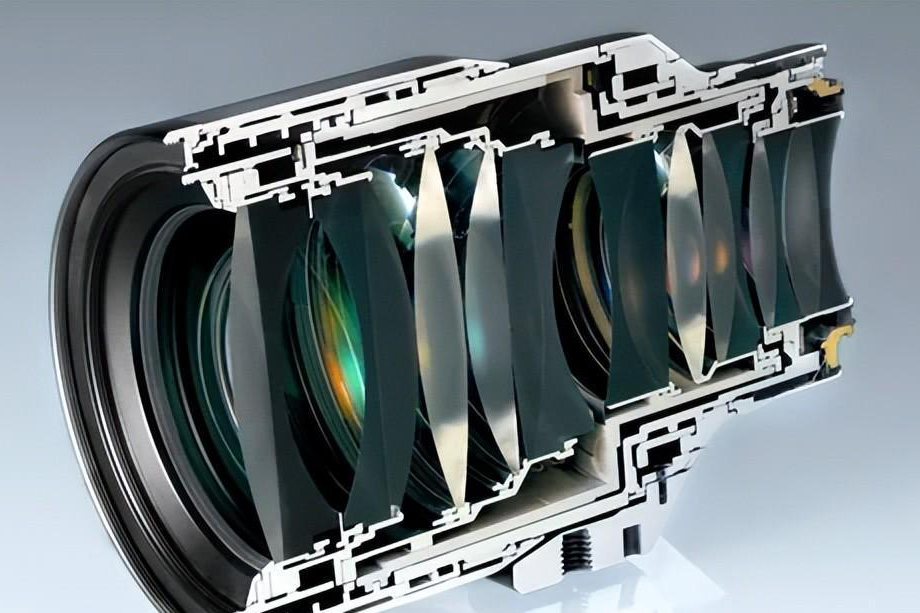

Imaging lenses are crucial components in optical systems, responsible for capturing and recording images. Through a combination of lenses, they gather light emitted from external objects and project a clear image onto an image sensor. The performance and design of imaging lenses directly impact the quality and clarity of the image.

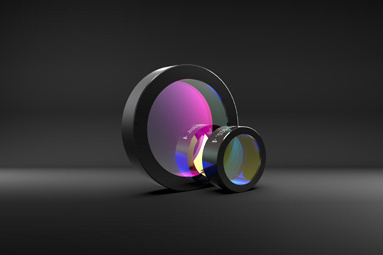

Optical coating refers to the process of depositing a single or multiple layers of metallic or dielectric thin films onto the surface of optical components. The purpose of coating optical components is to reduce or increase light reflection, beam splitting, color separation, filtering, polarization, etc. Common coating methods include vacuum deposition (a type of physical deposition) and chemical deposition.

Absorptive optical filter glass

A filter is an optical filter. It can filter out unwanted spectral components or interfering light in the incident light, reduce interference components in the background, improve the contrast of the target to the background, and thus improve the signal-to-noise ratio of the system.

Copyright©2025 Nanyang DuChuang Optoelectronic Technology Co., Ltd.